STEEL TYPE AND THE INNOVATIVE COVER OF PUNCH & DIE

Proper Steel Selection is Critical

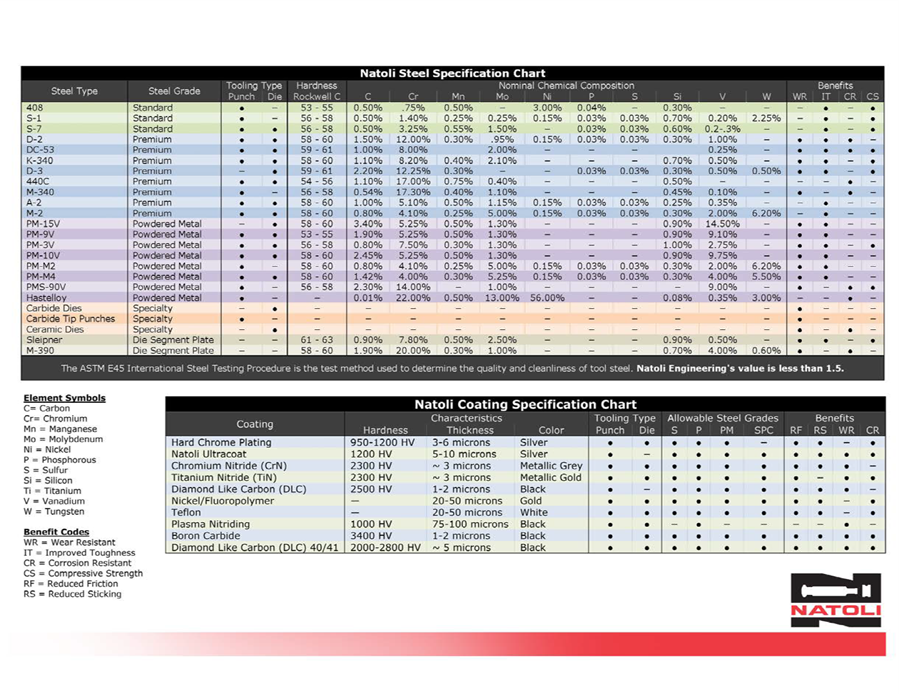

Natoli Engineering requires all steel to be Electroslag Refined (ESR) to ensure cleanliness and adhere to a strict internal carbide size and distribution standard. In addition to seeking the highest quality steel, we quarantine all incoming material until an outside laboratory verifies that all specifications and standards were met; ASTM A681- 06 or manufacturers specifications for chemistry and ASTM E45 Method D (Low Inclusion Content) to quantify cleanliness.

All Natoli steel is quality tested for composition and purity, and then measured against the strictest standards – making our tablet compression tooling the best in the industry.

Adhering to the strictest industry guidelines, we ensure our steel quality is not compromised by using the same test procedures established by the American Society of Testing and Materials.

Steel selection is critical to tablet production consistency and success. Using the “hardest” steel is not always the best choice, because hardness doesn’t always equate to the highest tensile strength, which may be required when utilizing multi-tip tooling.

Maintaining the industry’s largest inventory of tool steel ensures we have the punch and die steel on hand and ready to be customized to meet the exact requirements. Never wait for steel.

We wishes to provide our customers with the best tooling available. While we can tell you about our quality, we would rather show you.

Natoli inventories a one-year supply of 16 common grades of tool steel at our on-site facility: / Nguồn dự trữ thép cho sản xuất của chúng tôi luôn sẵn sàng trong 1 năm sử dụng, gồm 16 loại thép phổ biến:

- Standard Grade / Loại thép tiêu chuẩn: S-7, S-1, 3Ni

- Premium Grade / Loại thép cao cấp: D-2, DC53, A2, M-2, 0-1, K340

- Premium Grade Corrosion Resistant / High Chrome/ Loại thép cao cấp kèm thuộc tính kháng ăn mòn/ hàm lượng Chrome cao: 440-C, M340

• Premium Grade Specialty / Loại thép cao cấp đặc biệt: PM-3V, PM-9V, PM-10V, PM-15V, PM-M4

Steel Coatings

Quality Solutions for Tableting Complications

Many common tableting issues, such as sticking and picking, may be reduced by applying a specialized coating to your tooling. Our numerous coatings are designed to provide practical options based on the tablet formulation being compressed and to improve the quality and efficiency of your tableting operation.

Natoli has a specific coating solution to meet your every need. Whether you require enhanced product release or improved wear resistance, one of our coating options is sure to meet your requirements. For example, a chrome or chromium nitride coating will reduce the propensity for powders to adhere to the punch face. We also offer a proprietary coating, Natoli Ultracoat, which is superior to electro-process chrome and improves punch wear resistance, tool life, and lubricity, which reduces sticking.

Natoli Coating Specification Chart

Although specialized coatings for multi-tip tooling are generally reserved for problematic formulations, we do not recommend that you rely solely on coatings to compress a specific product. We typically recommend solving these compression problems by using a specific steel that posseses the same or better properties. We are happy to discuss your exact needs and the challenges you are facing that may require a specialized coating.