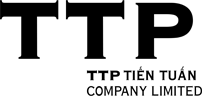

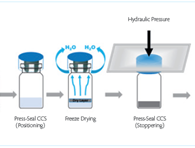

Liquid Filling Line

TTP Tien Tuan provides technologies for sterile filling systems on ophthalmic solutions and injectables, at the highest accuracy.

- The systems can fill vials and syringes for injectables, covering a wide range of product from 0,1ml till 500ml in vial and 0,1ml in syringes till 20ml.

- For ophthalmic solutions, we offer a huge range of bottles up to 500ml, with standard eye-drops introduction and screw capping, or systems like new aptar filtered cap.

Filling proposed systems starts from peristaltic pumps till complex ceramic rotary pump with CIP/SIP system integrated. This sterile filling solutions are offered with a high technology software to be in compliance with CFR 21 part 11, with track and trace control, Inline Process Control.

Our machines can be isolated with latest technology of Isolators for Biotechnology projects.

We can provide package supply as customer demands:

- Washing machine: rotary type or linear type

- Drying tunnel

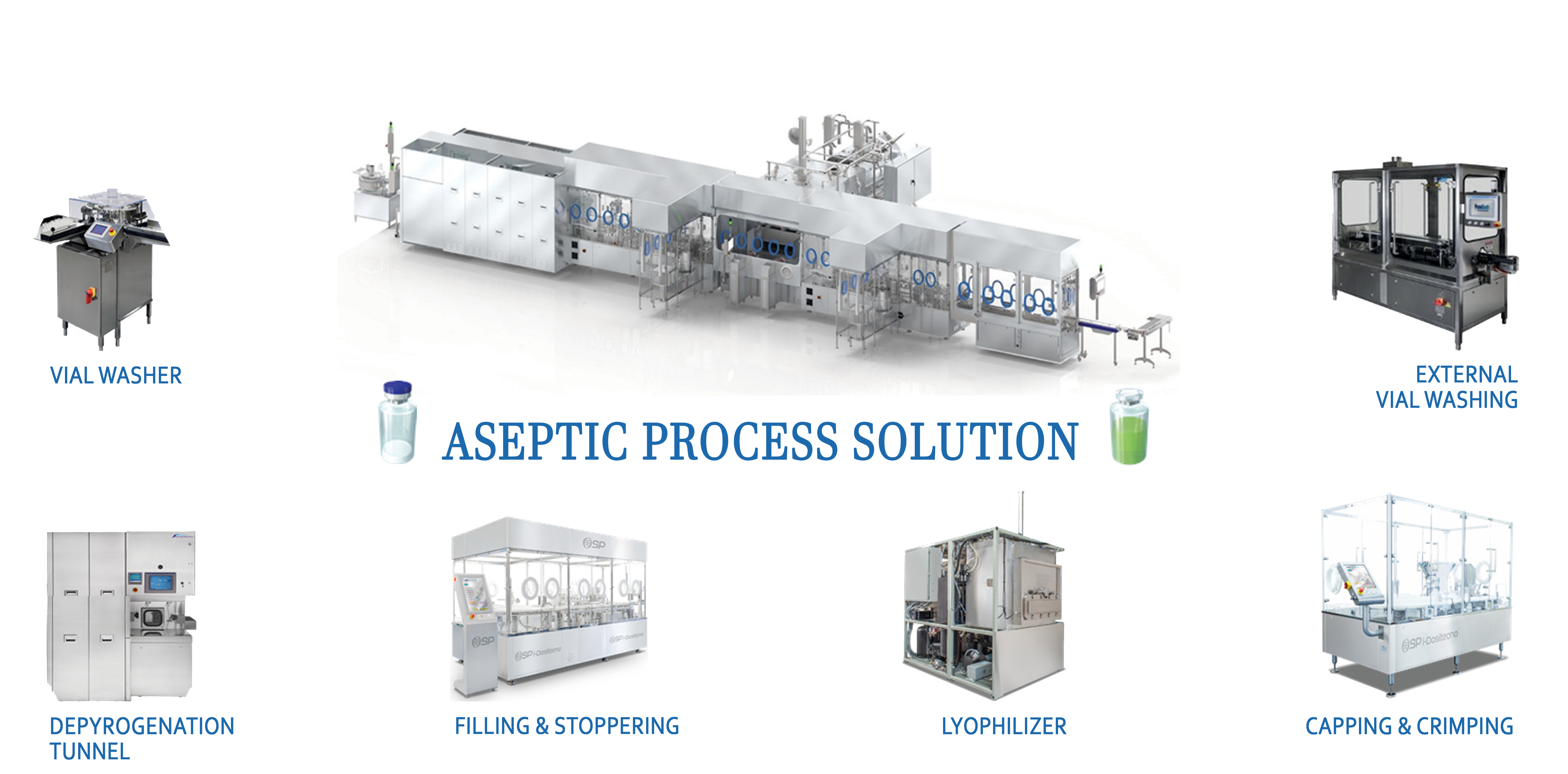

- Filling

- Stoppering

- Capping

- Labelling & rod inserting

We offer a very high standard solution for medium and low speed solutions, but with very high requirements. Our speed range covers till 9.000u/h. In this product range we can offer maximum benefits like Isolators for high containment solutions, oRAB’s and cRAB's, IPC control with check weighing of 100% of the production, CFR 21 part 11 compliance and smooth and accurate production.

Our equipment is able to work as per dehydrogenating tunnel or pre-sterilized vials, and suitable to be sterilized inline (with CIP/SIP equipment and H2O2) or by means of autoclave. Offering a complete package of Documentation as per Pharmaceutical cGMP and FDA requirements.

Model XI-I Series

Machine specially designed for sterile pharma filling, able to fill sterile liquid and sterile powder. Output up to 7.000 b/h.

- Filling, stoppering and crimping machine for vials

- Intermittent rotary filler for doses from 1ml to 500ml

- For formats up to 80 mm ø in simple configuration

- Maximum output 000/ hour. For formats up to 26 mm ø in double configuration 7.000/ hour

- Built as per cGMP, FDA standards

- Machine can be sterilized by H2O2, and without corners

- Machine can hold up to 8 heads

- Controlled through axes controlling system

- Machine completely servo driven

- Vials reject for no filled vials, no stopped vials, lower Lyo stoppered vials and no capsule vials

- No vial no fill

- Vials Filling by means of: Peristaltic pump, Stainless steel Rotary pump, Ceramic Rotary pump, CIP/SIP Rotary pump. Vacuum pressure filling system for micro-powder dosing, auger filler for micro-powder dosing 10mg

- 100% vials weighing IPC control

- Laminar Flow (LF)

- 21 CFR Part 11 compliance

- IQ, OQ, DQ documentation.

Model MI-I Series

Machine specially designed for sterile pharma filling, able to fill liquid and pharma powder. Output up to 6.000 b/h.

- Filling, stoppering and crimping machine for vials.

- Intermittent rotary filler for doses from 1 ml to 500ml.

- Machine to produce up to 6.000 b/h for injectable vials from 2R.

- From 12mm rubber stopper till 32mm.

- From 12mm alu-cap till 32mm alu-cap.

- Built as per cGMP, FDA standards.

- Machine can hold up to 4 heads.

- Star wheel, controlled by servomotor.

- No vial, no fill.

- Vials feeding by means of a loading tray

- Unloading tray.

- Vials Filling by means of: Peristaltic pump, Stainless steel Rotary pump, Ceramic Rotary pump, CIP/SIP Rotary pump. Vacuum pressure filling system for micro-powder dosing, auger filler for micro-powder dosing 10mg

- oRAB’s and LAF’s

- Debagging system to infeed presterilized vials

- 21 CFR Part 11 compliance

- IQ, OQ, DQ Documentation.

Model BI-I Series

Table top Machine specially designed for sterile filling, able to fill sterile liquid and sterile powders. Output up to 3.000 b/h.

- Filling, stoppering and crimping machine for vials.

- Intermittent rotary filler for doses from 1 ml to 250ml.

- Machine to produce up to 3.000 b/h for injectable vials from 2R.

- From 12mm rubber stopper till 32mm.

- From 12mm alu-cap till 32mm alu-cap.

- Built as per cGMP, FDA standards.

- Machine can hold up to 2 heads.

- Star wheel, controlled by servomotor.

- No vial, no fill.

- Vials feeding by means of a loading tray

- Unloading tray.

- Vials Filling by means of: Peristaltic pump, Stainless steel Rotary pump, Ceramic Rotary pump, CIP/SIP Rotary pump. Vacuum pressure filling system for micro-powder dosing, auger filler for micro-powder dosing 10mg

- oRAB’s and LAF’s

- Debagging system to infeed presterilized vials

- Isolator and cRAB’s

- 21CFR PART 11 COMPLIANCE

- IQ, OQ, DQ Documentation

We are offering a very high standard solution for medium and low speed solutions, but with very high requirements. Our speed range cover till 12.000u/h, our equipment is offering a complete sterile solution.

Our equipment can work with plastic bottles (pre-sterilized) with eye-drop and cap, with full servo solutions and suitable to be sterilized inline (with CIP/SIP equipment and H2O2) or by means of autoclave. Offering a complete package of Documentation as per Pharmaceutical cGMP and FDA requirements.

Model MI-O Series

Machine specially designed for laboratory, able to fill liquids (Ophthalmics). Output up to 6.000 b/h. Fill dose Simplex: 0.1ml – 250ml.

The machine is under cGMP, FDA standards, CE, UL and CFR21 part 11. Some available functions:

- Vials rejection

- Signalling lights

- IPC 100% weight control

- 100% torque control in capping unit.

- Laminar Flow (LF)

- cRABS, Isolators

- IQ, OQ, DQ.

Model LI-O Series

Machine specially designed for eye-drops with different formats. Output up to 12.000 b/h. Fill dose Simplex: 0.1ml – 250ml.

The machine is under cGMP, FDA standards, CE, UL and CFR21 part 11. Some available functions:

- Vials rejection

- Signalling lights

- IPC 100% weight control

- 100% torque control in capping unit.

- Laminar Flow (LF)

- cRABS, Isolators

- IQ, OQ, DQ